TECHNYL® Engineered Materials

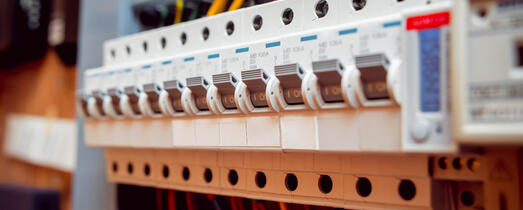

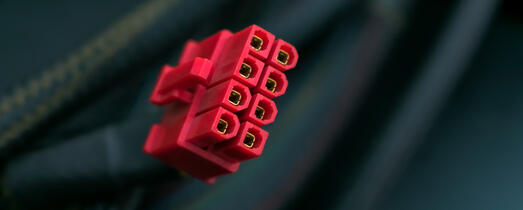

TECHNYL® is the brand of choice for pioneering polyamide-based solutions for automotive, electrical & electronics, building & construction, consumer & industrial goods, and more. Since 1953, TECHNYL® has offered the full range of polyamide 6 and 66 based solutions for a diverse range of applications used every day, around the world.

After acquiring Solvay’s European Performance Polyamides business in 2020, DOMO became the exclusive producer and distributor of TECHNYL® polyamides. DOMO has the privilege of providing the global market with this leading polyamide brand with a 70-year pedigree.